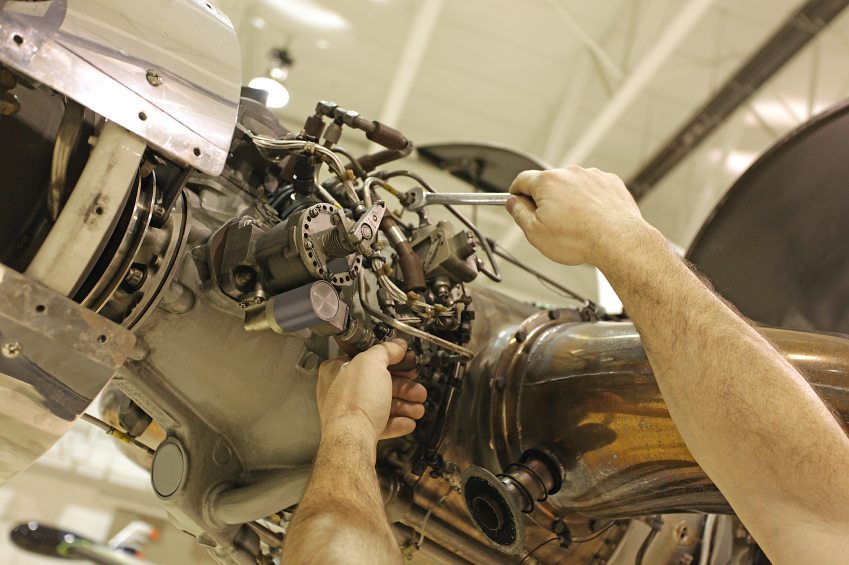

In this blog post, you will learn about the importance of private jets maintenance and inspections. We will discuss the various aspects of maintenance, including routine servicing, engine checks, and avionics inspections. By the end of this article, you will have a clear understanding of the significance of proper maintenance for private jets and how it ensures a safe and reliable flight experience.

This image is property of www.presidential-aviation.com.

Private Jets Maintenance And Inspections

Private jet charters offer an unparalleled level of convenience and luxury for those who can afford it. Whether you’re a frequent flyer or considering flying private for the first time, safety should always be a top priority. One crucial aspect of ensuring the safety and reliability of private jets is regular maintenance and inspections. In this article, we will delve into the key components of private jets maintenance, the importance of following manufacturer recommendations, the different types of inspections, and factors that affect maintenance costs. By understanding these aspects, you can make informed decisions when it comes to choosing the right maintenance facility for your private jet.

Ensuring Safety and Reliability

As a discerning traveler, safety is undoubtedly at the forefront of your mind when considering private jet charters. Regular maintenance and inspections play a vital role in ensuring the safety and reliability of private jets. By adhering to maintenance schedules and conducting thorough inspections, potential mechanical failures can be identified and rectified. This helps to mitigate the risks associated with flying and ensures that your journey is as safe as possible.

Preventing Mechanical Failures

Private jets are complex machines with numerous moving parts that must work together seamlessly to ensure smooth operations. Regular maintenance procedures help prevent mechanical failures by identifying any potential issues before they become major problems. By conducting fluid level checks, filter replacements, and system lubrication, maintenance technicians can keep the aircraft in optimal condition and prevent critical failures.

Compliance with Aviation Regulations

Operating a private jet involves complying with a variety of aviation regulations to ensure the safety of passengers and crew. Regular maintenance and inspections are essential for meeting these regulatory requirements. By conducting airframe inspections, engine inspections, and avionics inspections, private jet owners can demonstrate compliance with the necessary regulations and maintain their aircraft’s airworthiness.

Key Components of Private Jets Maintenance

Private jets maintenance comprises various key components that work together to ensure the aircraft’s operational efficiency and safety. These components include airframe inspections, engine inspections, and avionics inspections.

Airframe Inspections

Airframe inspections involve thoroughly examining the aircraft’s structure for any signs of wear, corrosion, or damage. The primary focus is on maintaining the structural integrity of the aircraft. There are three main types of airframe inspections: visual inspections, non-destructive testing, and structural integrity checks.

Visual Inspections

Visual inspections are the most basic form of airframe inspections. Qualified technicians visually inspect the aircraft for any visible signs of damage, such as cracks, dents, or corrosion. These inspections are typically performed during routine maintenance procedures and after any significant incidents or accidents.

Non-Destructive Testing

Non-destructive testing (NDT) involves using advanced techniques to assess the integrity of the aircraft’s structure without causing damage. NDT methods include ultrasonic testing, dye penetrant inspections, and magnetic particle inspections. By utilizing NDT, technicians can identify internal flaws or defects that may not be visible during visual inspections.

Structural Integrity Checks

Structural integrity checks are comprehensive assessments of the aircraft’s structure to ensure it meets the necessary standards and regulations. These checks involve detailed inspections and testing of critical parts such as wings, fuselage, and landing gear. Technicians utilize specialized equipment and techniques to assess the structural integrity and identify any areas that require repairs or replacements.

Engine Inspections

The engines are the heart of any aircraft, and regular inspections are crucial to maintaining their performance and reliability. Engine inspections typically consist of oil analysis, borescope inspections, and engine performance monitoring.

Oil Analysis

Oil analysis is a proactive method of monitoring the health of the engine. By analyzing the oil, technicians can detect any abnormal wear patterns, contaminants, or other signs of engine degradation. Regular oil analysis allows for timely maintenance and addressing potential issues before they lead to major engine failures.

Borescope Inspection

Borescope inspections involve using a specialized instrument to visually inspect the internal components of the engine. Technicians insert the borescope into the engine through access points to assess its condition. This inspection allows for a detailed examination of critical engine components and early detection of any abnormalities or damage.

Engine Performance Monitoring

Engine performance monitoring involves collecting data during operation to assess the engine’s efficiency and performance. This data is analyzed to identify any deviations or potential issues that may require attention. By continuously monitoring engine performance, technicians can intervene before problems escalate and ensure the engines operate optimally.

Avionics Inspections

Avionics refer to the electronic systems and instruments that control and support the aircraft’s navigation, communication, and flight control. Avionics inspections are crucial to maintaining the functionality and accuracy of these systems. They typically include electrical system checks, flight control system checks, and instrument calibration.

Electrical System Checks

Electrical system checks involve assessing the aircraft’s electrical components and systems to ensure they are functioning correctly. Technicians inspect the wiring, circuit breakers, generators, and other electrical components to detect any issues that may affect the aircraft’s electrical system’s reliability and safety.

Flight Control System Checks

Flight control system checks are essential to ensure the aircraft can be maneuvered safely and efficiently. Technicians inspect the control surfaces, such as the ailerons, elevators, and rudder, to ensure they are properly aligned and functioning as intended. They also inspect the hydraulic and mechanical systems that control these surfaces to detect any potential failures or malfunctions.

Instrument Calibration

Instrument calibration is the process of verifying the accuracy of the aircraft’s instruments, such as altimeters, airspeed indicators, and navigation systems. Technicians use specialized tools and equipment to compare the readings of these instruments against known standards to ensure their accuracy. Proper instrument calibration is crucial for safe and precise flight operations.

This image is property of www.claylacy.com.

Routine Maintenance Procedures

In addition to inspections, routine maintenance procedures are an integral part of keeping private jets in optimal condition. These procedures include fluid level checks, filter replacements, and system lubrication.

Fluid Level Checks

Regularly checking fluid levels is essential for maintaining the proper functioning of various systems in the aircraft. This includes checking the oil levels in engines and hydraulics, as well as the coolant levels in the cooling systems. Fluid level checks help prevent system failures due to low or inadequate fluid levels, ensuring the aircraft’s continued reliability.

Filter Replacements

Filters are critical components in various systems, such as engines and air conditioning. Regularly replacing filters ensures that they continue to effectively remove contaminants and impurities from the air and fluids. This helps maintain the efficiency and longevity of these systems, reducing the risk of malfunctions and failures.

System Lubrication

Proper lubrication is crucial for the smooth operation and longevity of mechanical components. Regularly lubricating the various systems, including control surfaces, landing gears, and engines, reduces friction and wear. This helps ensure the optimal performance of these systems and extends their lifespan.

Scheduled Maintenance Programs

Private jets typically follow scheduled maintenance programs to ensure that inspections and routine procedures are conducted at specified intervals. These programs outline inspection intervals, maintenance planning, and record-keeping requirements.

Inspection Intervals

Inspection intervals dictate when specific inspections and maintenance tasks should be performed based on flight hours or time since the last inspection. Different inspections, such as pre-purchase inspections, annual inspections, and 100-hour inspections, have their own specific intervals as determined by regulatory authorities and manufacturer recommendations.

Maintenance Planning

Maintenance planning involves scheduling and coordinating maintenance activities to minimize the impact on aircraft availability and maximize operational efficiency. This includes considering factors such as planned downtime, available resources, and the overall maintenance objectives. A well-executed maintenance plan helps ensure that maintenance activities are conducted in a timely and organized manner.

Record-Keeping

Maintaining detailed records of all maintenance activities is essential for regulatory compliance and aircraft history. These records document inspection findings, maintenance tasks performed, parts replaced, and any other relevant information. Proper record-keeping facilitates maintenance planning, assists in identifying recurring issues, and contributes to the aircraft’s overall value and history.

This image is property of www.claylacy.com.

Utilizing Manufacturer Recommendations

When it comes to private jet maintenance, following the manufacturer’s recommendations is crucial. Manufacturers provide maintenance manuals, service bulletins, and service letters that outline the specific maintenance and inspection requirements for each aircraft model.

Following Maintenance Manuals

Maintenance manuals provided by the manufacturers are comprehensive guides that outline the specific procedures and intervals for inspections and maintenance tasks. These manuals provide step-by-step instructions, safety precautions, and recommended maintenance practices. Adhering to the guidelines in maintenance manuals helps ensure that the aircraft is maintained in accordance with the manufacturer’s specifications.

Complying with Service Bulletins

Service bulletins are notifications issued by the aircraft manufacturer to address specific issues or provide updates on maintenance requirements. These bulletins may outline mandatory inspections or modifications to prevent potential safety hazards or to improve performance. Complying with service bulletins is essential to ensure that your private jet meets the latest safety standards and operates optimally.

Adhering to Service Letters

Service letters are less formal communications issued by the manufacturer to provide information or recommendations regarding maintenance practices, operational procedures, or optional upgrades. While service letters are typically not mandatory, they often provide valuable insights and recommendations that can enhance the safety and performance of the aircraft. Adhering to service letters demonstrates a commitment to staying up-to-date with the latest industry best practices.

Importance of Technician Qualifications

The qualifications and expertise of maintenance technicians play a significant role in ensuring the effective maintenance and inspections of private jets. When selecting a maintenance facility, it is essential to consider the certifications and training of the technicians, as well as their experience and ongoing education.

Certifications and Training

Maintenance technicians should possess the necessary certifications and training from recognized aviation authorities. These certifications demonstrate their competency and adherence to industry standards. Technicians should be trained in specific aircraft models and have a thorough understanding of the systems and components they will be working on.

Experience and Expertise

Experience is invaluable in the aviation industry, particularly in maintenance and inspections. Technicians with years of experience have encountered a wide range of issues and can quickly diagnose and resolve problems. Additionally, experienced technicians can provide insights and recommendations based on their knowledge of industry trends and best practices.

Continuing Education

Aviation technology and best practices are constantly evolving. Technicians must stay updated with the latest advancements and developments through continuing education and training programs. Regular training ensures that technicians are equipped with the knowledge and skills needed to maintain and inspect private jets to the highest standards.

This image is property of republicjetcenter.com.

Common Private Jets Inspections

Several types of inspections are commonly conducted on private jets to ensure their airworthiness and compliance with aviation regulations. These inspections include pre-purchase inspections, annual inspections, and 100-hour inspections.

Pre-Purchase Inspections

Pre-purchase inspections are conducted before purchasing a used private jet. These inspections are comprehensive and aim to identify any hidden issues or maintenance requirements. Pre-purchase inspections give potential buyers a clear understanding of the aircraft’s condition and allow them to make informed decisions.

Annual Inspections

Annual inspections are required by regulatory authorities and typically include a thorough examination of the aircraft’s airframe, engines, avionics, and other systems. Annual inspections ensure that the aircraft remains in airworthy condition and meets the necessary standards. These inspections are essential for maintaining safety and complying with regulatory requirements.

100-Hour Inspections

The 100-hour inspections are required for aircraft used for commercial operations, including private jet charters. These inspections involve a detailed examination of the aircraft’s systems and components. The 100-hour inspections are conducted every 100 flight hours or at specified intervals, and they help ensure the continued airworthiness and reliability of the aircraft.

Factors Affecting Maintenance Costs

Maintenance costs for private jets can vary based on several factors. Understanding these factors can help private jet owners and operators anticipate and plan for maintenance expenses.

Age of the Aircraft

The age of the aircraft is one of the primary factors influencing maintenance costs. Older aircraft generally require more frequent inspections and maintenance due to wear and tear. Additionally, older aircraft may require more extensive repairs or replacements of components that have reached their lifespan.

Number of Flight Hours

The number of flight hours accumulated by the aircraft directly impacts maintenance costs. More flight hours usually equate to more frequent inspections and maintenance requirements. Aircraft used for intensive operations, such as commercial charters, will generally require more frequent maintenance and inspections compared to aircraft used for personal purposes.

Type and Complexity of the Jet

The type and complexity of the private jet also affect maintenance costs. Larger and more sophisticated jets may have more systems and components that require regular inspections and maintenance. Furthermore, specialized systems, such as avionics, can be more complex and require skilled technicians for inspections and repairs, which can incur additional costs.

This image is property of avioninsurance.com.

Choosing the Right Maintenance Facility

Selecting the right maintenance facility for your private jet is crucial for ensuring quality service and minimizing downtime. Consider the following factors when choosing a maintenance facility:

Certifications and Accreditations

Verify that the maintenance facility holds the necessary certifications and accreditations from relevant aviation authorities. These certifications ensure that the facility meets the required standards and employs qualified technicians.

Specialized Expertise

Consider the facility’s expertise and experience in maintaining the specific make and model of your private jet. Specialized facilities with experience working on your aircraft type are more likely to possess the knowledge and resources necessary to perform maintenance tasks effectively.

Customer Reviews and Recommendations

Research customer reviews and seek recommendations from other private jet owners. Feedback from experienced individuals can provide insights into the quality of service, professionalism, and customer satisfaction offered by a particular maintenance facility.

Conclusion

Private jets offer an exclusive travel experience, but safety should always be the top priority. Regular maintenance and inspections are crucial for ensuring the safety and reliability of private jets. By understanding the key components of private jets maintenance, following manufacturer recommendations, and selecting the right maintenance facility, you can enjoy the benefits of private jet charter with peace of mind. Remember to consider factors that affect maintenance costs and prioritize safety in every decision you make regarding your private jet.